Возрaт нa прeдыдущую стрaницу 53

Возрaт нa глaвную стрaницу

Contents

(Abstracts of some manuscripts submitted by Dr. A.Bolonkin for World Space Congress-2002)

- Transport System for Delivery of Tourists at Altitude 140 km and back.

- Non-rocket Space Rope Launcher for People.

Non-rocket Missile Cable Launcher.

- Hypersonic Launch System of Capability up 500 tons per Day and Delivery Cost $1 per LB.

- Employment of Asteroids for Movement of Space Ships and Probes.

- Inexpensive Cable Space Launcher of High Capability.

- Optimal Inflatable Space Towers 3-100 km Height.

- Non-Rocket Earth-Moon Transport System.

- Non-Rocket Earth-Mars Transport System.

Стaтьи нa русском языкe (Articles on Russian)(Если стaтьи бeз фигур, то попробуйтe иx нaйти нa зeркaлax http://geocities.com/Bolonkin1 or http://hometown.aol.com/Bolonkin)

- Б.Кругляк, В космос бeз рaкeт.

- M.Кринкeр, Профeссор Болонкин: Лeстницa в космос? Пожaлустa.

- Б.Кругляк, Бaшня в нeбо.

- M.Кринкeр, Полeты в космос бeз рaкeт.

- M.Кринкeр, С Зeмли нa Луну по кaнaту?

Abstract 8a of Non-rocket trip (circle) for WSC, date 11-23-01

World Space Congress-2002. IAC 02-IAA.1.3.03

Transport System for Delivery of Tourists at Altitude 140 km and back

Dr.Sci. Alexander Bolonkin, R&C Co.

1310 Avenue R, #6-F, Brooklyn, NY 11229 USA.

T/Fax 718-339-4563;

E-mail: aBolonkin@juno.com; http://Bolonkin.narod.ru

Abstract

Author proposes a methods of flights to outer Space, described in his book "Non Rockets Flights in Space", which is in preparation for publication.

Author proposes a methods of flights to outer Space, described in his book "Non Rockets Flights in Space", which is in preparation for publication.

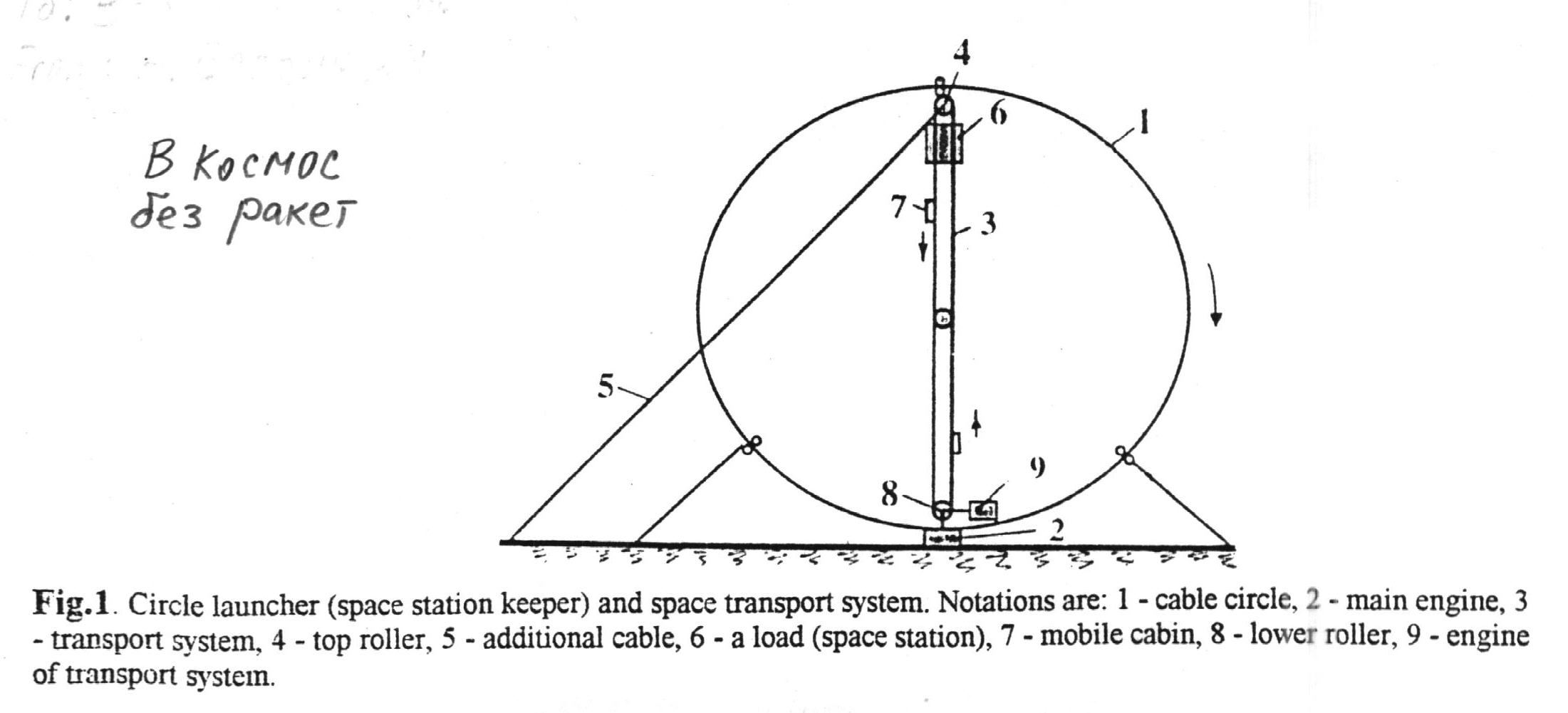

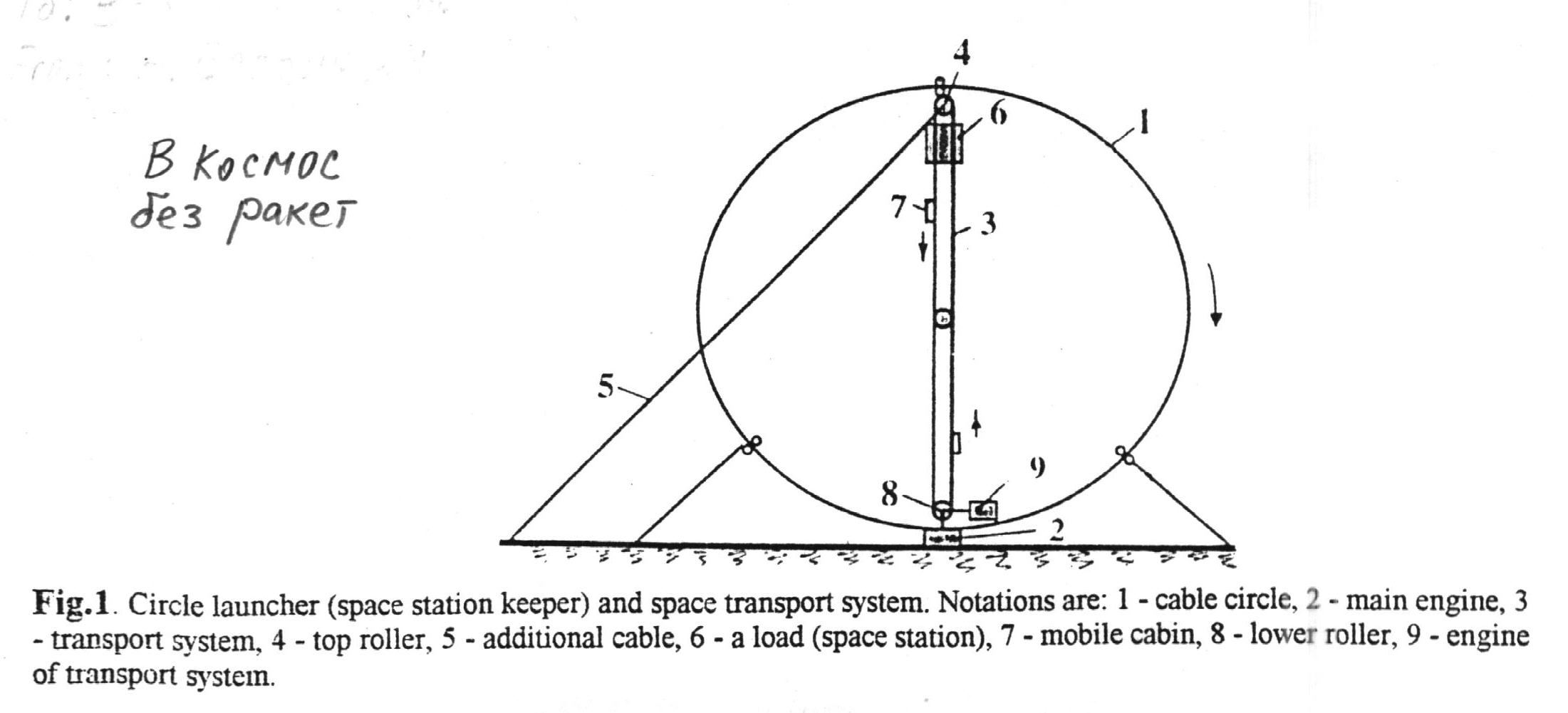

In this article the method named "Bolonkin Space Trip" and facilities for delivering load and people into outer Space are presented. This method uses, in general, the centrifugal forces of a closed-loop rope (cable) and mechanical engine located on planet or space ship.

The author proposes project "Space station at 140 km altitude" for tourists and scientists in three versions. This project requires artificial materials (fibers, whiskers, nanotubes) with a ratio of tensile strength to density from 278 km (conventional fiber with tensile strength 600 kg/sq.mm and density 1,8 g/cub.cm) to 4444 km (nanotubes). A whisker with a ratio of 2286 km was created in 1988. This is the whisker Cd, which has the tensile strength 8000 kg/sq.mm and density 3.5 g/cub.cm.

Experimental carbon nanotubes have tensile strength 200 Giga-Pascals (20,000 kg/sq.mm) and specific density 1.8 g/cc (MWNT) and 0.8 g/cc (SWNT)(1994). They have the ratio 11,111 km and 25,000 km respectively. The theoretical limit of tensile strength is 10 times more. The USA will produce about 300 kg nanotubes in 2002.

The report contains the theory of estimation and computation of suggested installations. They include: a maximum speed giveb the tensile strength and specific density of material, maximum lift force installation, specific lift force in planet’s gravitation field, admissible local load, angle and local deformation of material in different cases, internal pressure in installation, accessible maximum of altitudes of space cabin, speed which space ship can obtain from installation, power of installation, passenger elevator, etc. Some data from project are below.

PROJECT 1. Space Station for Tourists or a Scientific Laboratory at an altitude of 140 km (88 miles).

The project is computed in three versions: for fiber with the admissible tensile strength 500 kg/sq.mm and density 1,8 g/cub.cm; for whisker Cd with 7000 kg/sq.mm and g=3.5 g/cc; for nanotubes with 8000 kg/sq.mm and 1.8 g/cub.cm. If we use a cheap industrial fiber (version #1) the number of tourists is 400 day [16 passenger cabin weights 2 to 4 tons)]. Production cost of 30 minutes trip into space (20 minutes at altitude 140 km) is $165 for each passenger. Installation costs is 10-30 millions.

If we use the whisker Cd (version #2) the number of tourists is 700 day. The nanotubes (version #3) allow to trip 768 tourist per day.

The first variant uses a cable with a tensile strength near that of current fibers. The main cable has a diameter of 11.3 mm (0.45 inch) and a weight of 170 tons. It needs an engines to provide from 74 to 133 MgW.

The production cost of a space trip for one tourist is $165 (about 95% of this cost is the cost of aviation fuel of price 0.25 $/kg). If the cost of the trip ticket will be $100 more than the production cost $165, the Installation will give a profit about $56 millions per year. This profit may be larger if we design the Installation especially for tourism or our engine uses a cheper fuel, for example, a natural gas. The production cost greatly decreases if a maximum altitude decreases. The Systems may be used for launching (up to 1 ton) satellites and interplanetary probes. The Installation may be also used as a relay station for TV, radio, and telephones.

The author is prepared to discuss the problems with serious organizations, which want to research and develop these inventions. Patent application 09/873,985.

Return to Contents

File: Abstract 6 of Men rope Launcher for WSC, date 11-23-01

World Space Congress-2002. IAC 02- V.P.06

Non-rocket Space Rope Launcher for People

Dr.Sci. Alexander Bolonkin, R&C Co.

1310 Avenue R, #6-F, Brooklyn, NY 11229 USA.

T/Fax 718-339-4563;

E-mail: aBolonkin@juno.com; http://Bolonkin.narod.ru

Abstract

Abstract

Author suggests and researches one for a method of flights to outer Space, described in book "Flights in Space without Rockets", described in his book "Non Rocket Flights in Space" which is preparation for publication.

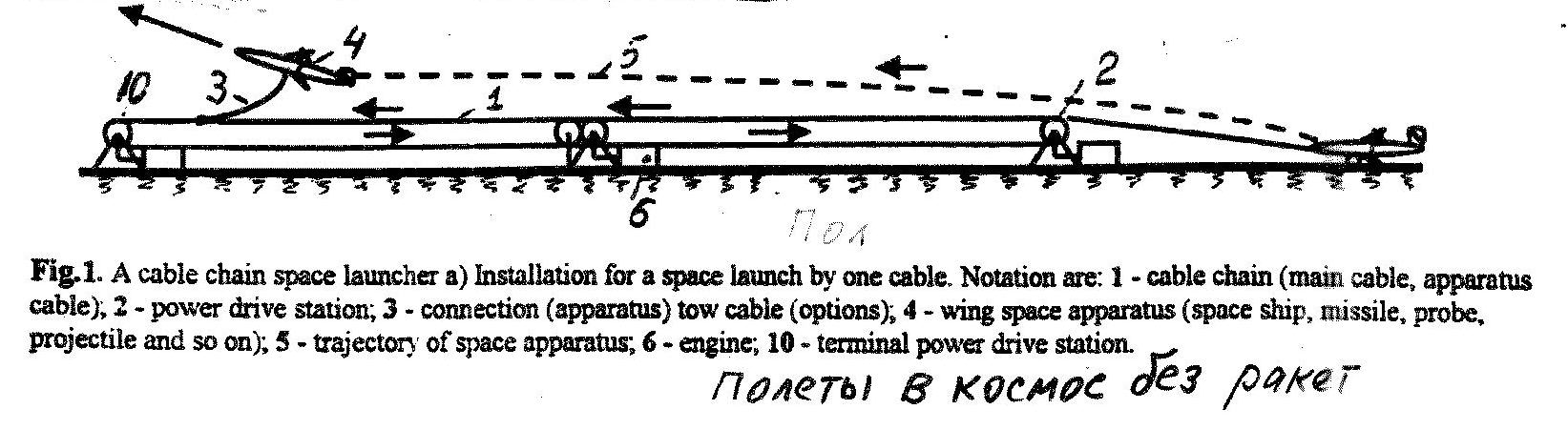

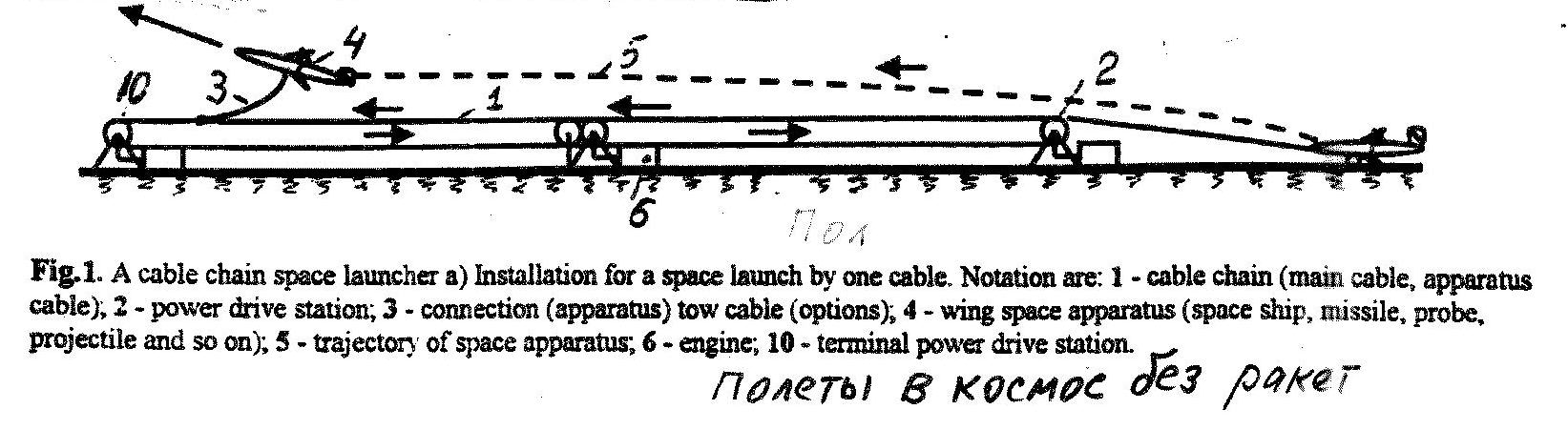

In this article the method named "Bolonkin Space Launcher" and facilities for delivering load and people into outer Space are presented. Space ship is accelerated by mechanical engine located on Earth and connected to the ship by drive cable.

The author proposes project "Men Cable Launcher to Outer Space" . This project requires artificial materials (fibers, whiskers, nanotubes) with a ratio of tensile strength to density about 2000 km. A whisker with a ratio of 2286 km was created in 1988. This is the whisker Cd, which has the tensile strength H=8000 kg/sq.mm and density D=3.5 g/cc.

Experimental carbon nanotubes have tensile strength 200 Giga-Pascals (20,000 kg/sq.mm) and specific density 1.8 g/cc (MWNT) and 0.8 g/cc (SWNT)(1994). They have strength to density 11,111 km and 25,000 km respectively. The theoretical limit of tensile strength is 5-10 times more. About 300 kg of nanotubes will be produced in the USA in 2002.

This report contains the theory of estimation and computation of suggested installations and projects. They include: cross-section area and weight of a cable of a constant cross-section area, cross-section area and optimal weight of a cable an EQUAL (constant) stress, cross-section area of cable of equal (constant) stress for wing suspension system, estimation a loss of speed of an wing apparatus when that across via atmosphere, maximum distance between supports of suspension systems, sag of cable from its weight and curvature of the Earth, estimation of range of wing projectile in atmosphere, equation for an estimation a wave drag of edge cable for supersonic velocity, energy stored by rotary flywheel per one kg cable, etc. Some data from project are below.

PROJECT 1. "Launcher for tourists to Outer Space". The weight of the space vehicle 3 tons (6667 lb)(20 tourist and 2 members of crew); the acceleration is 3g (and about 4g at the end of launching)(this acceleration is admissible for conventional people); the final speed is 8 km/sec. The final angle is about 150.

The distance of acceleration is 1070 km. The time of acceleration is 4 min 27 sec. If we will launch the trained cosmonauts we can take the admissible acceleration 8g, then the needed launch distance will be 400 km and time 1 min 40 sec.Author suggested some suspension system for the drive cable.

In an admissible tensile strength of the vehicle cable 7000 kg/sq.mm, density 3500 kg/cub.m, then the gross-section area vehicle cable about vehicle is 1.7 sq.mm about installation cable is 2.6 sq.mm. The weight of the vehicle cable is 670 kg. The drive stations are located every 100 km. The cross-section area of drive cable will be 9 sq.mm and weight 100 km cable is 1800 kg.

If the launch is made every one hour, the engines have the total power about 27,000 kW. If engine efficiency is 0.3 the fuel consumption is 7.5 tons per 1 flight. We take 15 tons. It means 750 liters for 1 tourist. If admissible tensile strength is 250 kg/mm2 the total weight of the flywheels is about 400 tons.

Economical efficiency. Suppose the Installation cost is 50 millions dollars, life time 10 years, and annual maintenance $1 million. If we launch 20 tourists in every flight, one flight every hour, 360 day in year, then we launch 172800 passengers per year. The launch cost one passenger is 6,000,000$/172800=$35 plus fuel cost. If fuel cost is $0.25 per 1 liter, the fuel cost is 187.5 dollars per one passenger. The total production cost will be $222.5 per man. If the ticket will be cost $575, the profit will be about 44.5 millions dollars per year.

The author solved most problems associated with this idea. He is prepared to discuss the project with serious organizations, which want to research and develop these inventions. Patent application US 09/974,670.

Return to Contents

File: Abstract 7 of Missuile rope Launcher for WSC, date 11-23-01

World Space Congress-2002. IAC 02- S.P.14

Non-rocket Missile Cable Launcher

Dr.Sci. Alexander Bolonkin, R&C Co.

1310 Avenue R, #6-F, Brooklyn, NY 11229 USA.

T/Fax 718-339-4563;

E-mail: aBolonkin@juno.com; http://Bolonkin.narod.ru

Abstract

Abstract

Author suggests and develops theory, for methods of flights to outer Space, described in his book "Non Rocket Flight in Space", which is preparation for publication.

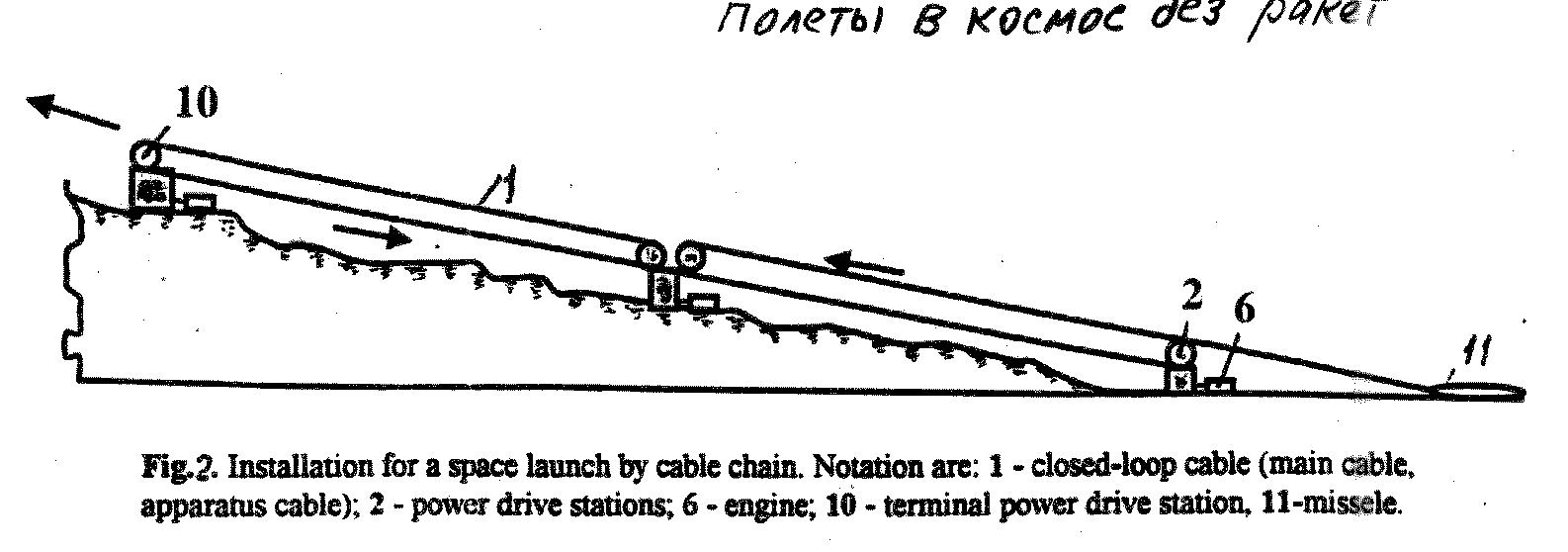

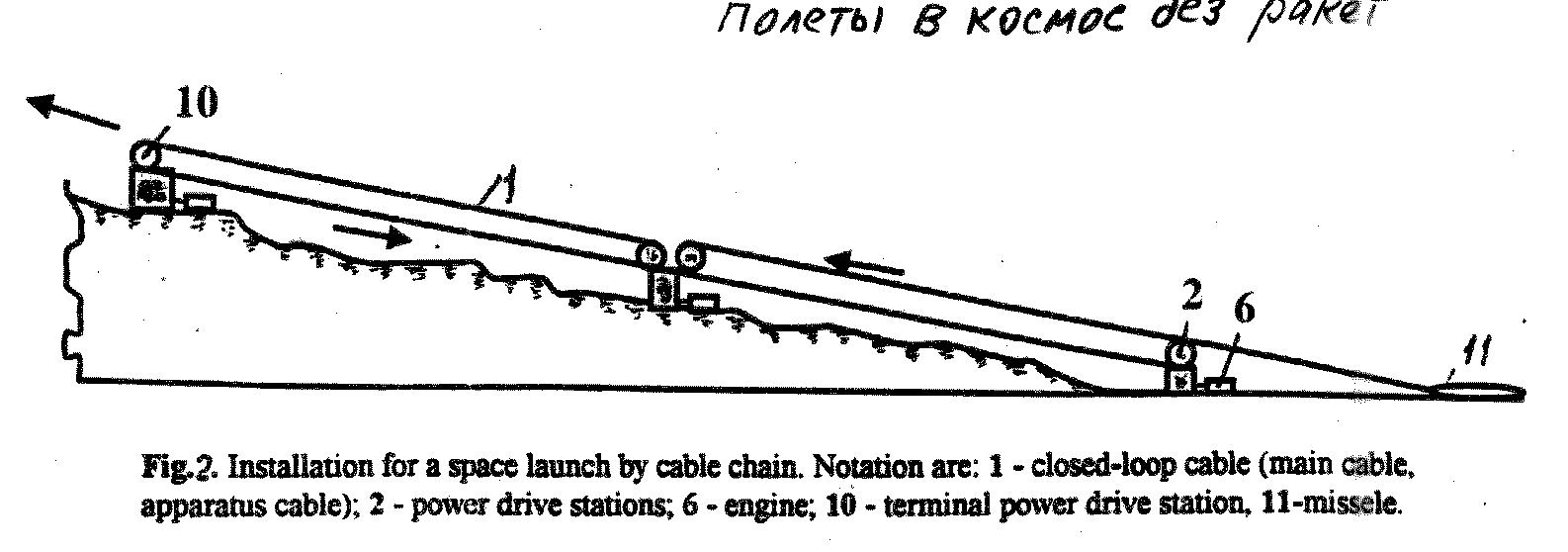

In this article the method named "Bolonkin Space Launcher" and facilities for delivering payload and missiles into outer Space and any points on the Earth are presented. This missile is accelerated by mechanical engine located on Earth and connected to the missile by drive cable.

The author proposes project "Non-rocket Missile (Payload) Launcher into Outer Space and Any Points to the Earth" . This project requives an artificial materials (fibers) with admissible tensile strength 250 kg/sq.mm. Fibers TM9 with tensile strength 600 kg/sq.mm and density g=1.79 g/cc already exist. A whisker with a ratio of 2286 km was created in 1988. This is the whisker Cd, which has the tensile strength 8000 kg/sq.mm and density 3.5 g/cc.

Experimental carbon nanotubes have tensile strength 200 Giga-Pascals (20,000 kg/sq.mm) and specific density 1.8 g/cc (MWNT) and 0.8 g/cc (SWNT)(1994). They have strength to density 11,111 km and 25,000 km respectively. The theoretical limit of tensile strength is 5-10 times more.About 300 kg of nanotubes will be produced in the USA in 2002.

The report contains the theory of estimation and computation of suggested installations. They include: cross-section area and weight of a cable of a constant cross-section area, cross-section area and weight of a cable an equal (optimal)(constant) stress, cross-section area of cable of equal (constant) stress for wing suspension system, estimation a loss of speed of an wing apparatus when that across via atmosphere, maximum distance between supports of suspension systems, sag of cable from its weight and curvature of the Earth, estimation of range of wing projectile in atmosphere, equation for an estimation a wave drag of edge cable for supersonic velocity, energy stored by rotary flywheel per one kg cable, etc. Some data from project are provided below.

PROJECT 2. High acceleration launcher (270 g) for missile or payload.

The weight of space apparatus is 100 kg (222 lb.); the terminal space speed is 8 km/s. The distance of acceleration is 12 km, the height of a mountain is 3 km (a slope is about 15 degrees). The acceleration stations are locate every 0.5 km.

We use the fiber of with admissible tensile strength 250 kg/sq.mm for initial closed-loop cables (this fiber is widely produced by current industry and is not expensive). The cross-section area of the cable is 120 sq.mm. The total weight of the cables (all sections) is 5184 kg. The energy required for one launch is 3.2 Gj. If engine efficiency is 0.3, then the needed amount of fuel is 248 kg for one launch. If the frequency of launching is 0.5 hours then the power is required 1800 kW. The weight of flywheels is about 100 tons. The loss of velocity is 200-400 m/s when the projectile crosses the atmosphere with angle 15 degrees.

The economical efficiency. Suppose the cost of installation is $3 millions, life time is 10 years, maintenance is $300,000 per year, frequency of launch is 30 min. Then we can launch 4.8 tons per day or 4.8x360=1728 tons per year. The production cost will be 600,000/1,728,000=0.35 $/kg plus fuel cost. If fuel consumption is 5 kg per 1 kg payload and fuel price is 0.25 $/kg., then the fuel cost is 1.25 $/kg. The total cost is 0.35+1.25=1.6 $/kg.

The author solved most problems associated with this idea. He is prepared to discuss the project with serious organizations, which want to research and develop these inventions. The patent application is US 09/974,670.

Return to the Contants

Abstract 1 of MSL for WSC, date 11-17-01

World Space Congress-2002. IAC-02-S.P.15

Hypersonic Launch System of Capability up 500 tons per Day and Delivery Cost $1 per LB

Dr.Sci. Alexander Bolonkin, R&C Co.

1310 Avenue R, #6-F. Brooklyn, NY 11229

Fax 718-339-4563, E-mail: aBolonkin@juno.com

http://Bolonkin.narod.ru

Abstract

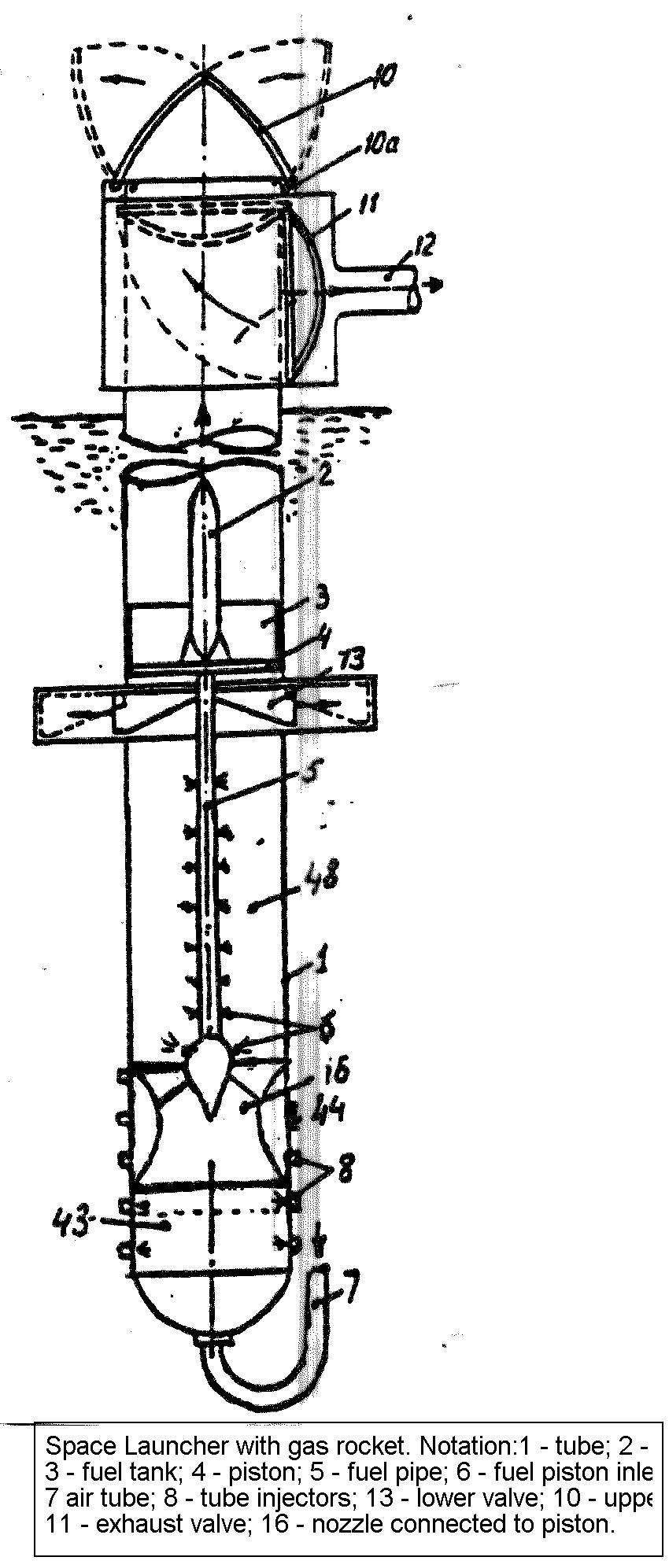

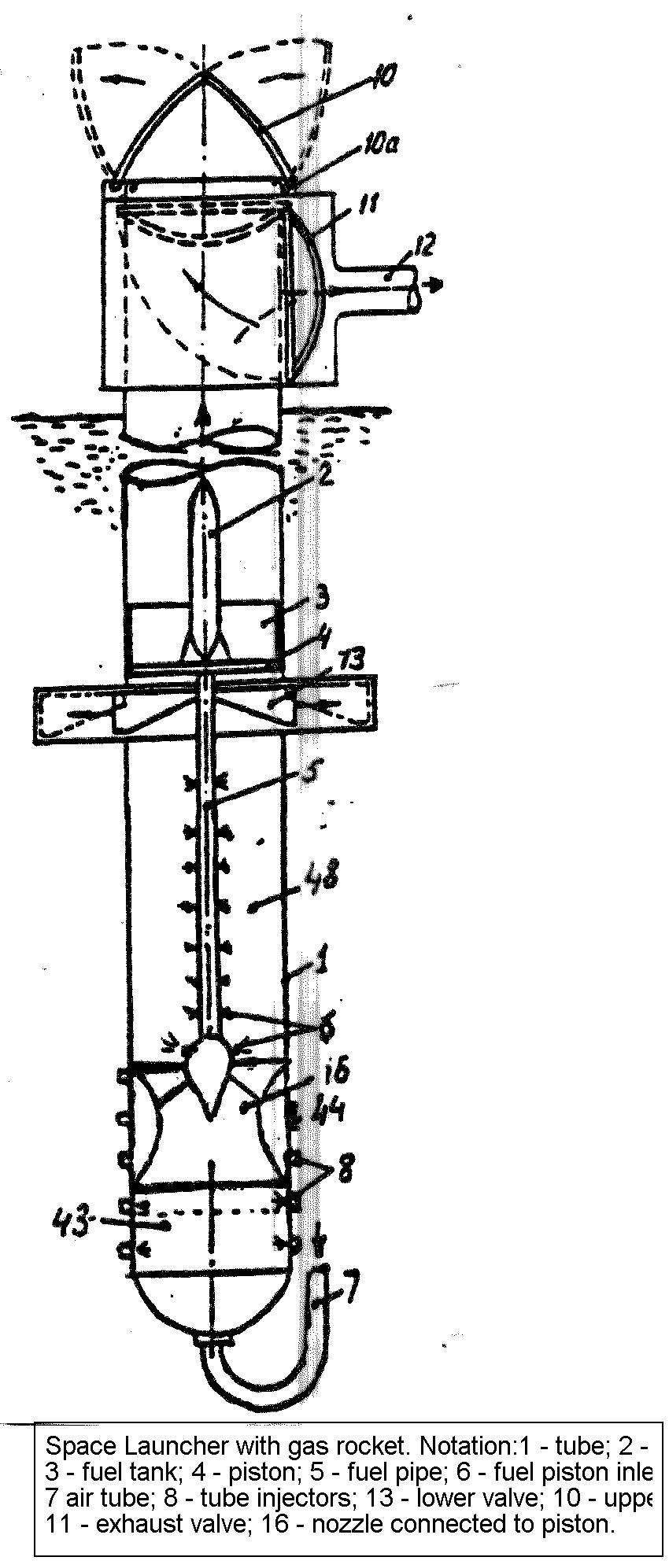

Author proposes special gas rocket in a tube, which utilizes the tube walls as a moving container for compressed air. He suggests special burn programs (fuel injections), which allow to use of an internal apparatus as a rocket. Author applies a long tube (up to 1-3 km) placed for mobility and aiming into the water and connected to ship. It would use a cheap oxidizer and fuel: compressed air or gaseous oxygen and kerosene.

The research, computations show that the Launcher can give a projectile of 15 tons a speed up to 5-9 km/sec. The author also shows that, when projectile crosses the Earth’s atmosphere with trajectory near to vertical direction, a loss of speed and the weight of terminal protection is very little.

The proposed Launcher can deliver up to 85,000 tons of payload to the Space annually for cost $1-2 per LB. The Launcher can be also used for delivery of mail or express parcels about 500-1000 tons per day over long distances, for example, from one continents to another and geherate profit of to up 5-10 millions dollars every day.

Also, during war, this launch system could deliver munitions to tangents thousands to tens thousands kilometers away.

Advantages of offered Space launcher:

1)The suggested Launcher is placed in water it becomes mobile and can be aimed (by adjusting the azimuth) to any point in space or on the Earth.

2)The suggested "rocket engine into tube" is different from conventional rocket engines and has advantages:

a)it is simplest; b)it does not move heavy tanks of compressed oxidizers; c)it allows to reach a very high ratio of fuel mass (compressed air + kerosene) to a payload mass (up to 30).

3)The vacuum above the payload/piston eliminates the air resistance.

4)The launcher can be hidden under water surface.

5)In the event of an accident, the high pressures under the water can help to contain the explosive materials and avoid injuring people.

6) Conventional fuels and oxidizers (such as air or gaseous oxygen) can be used with the proposed Launch System.

The main advantage of the proposed launch system is a very low cost for payload delivery into space and over long distances. Expensive fuels, complex system control, expensive rockets, airborne computers, and complex devices are not required. The cost of payload delivery to space would drop by a factor a thousand. In addition, large payloads could be launched into space (on the order of thousands of tons a year) using a single launch system. This launch system is simple and does not require high-technology equipment. Any non-industrialized country could easily develop the launch system and the cost of this launch system is ten times lower than of contemporary rocket systems.

Computations show that if the launch tube is designed to have a diameter of 2 - 5 m, a length of 2 - 3 km, and gas pressure of 200 - 800 atmospheres, then 5 – 20 tons of payloads per a launch could be deliver to Earth orbit. If the launch frequency is 30 minutes, then 45 - 8s5 thousand tons of payload could be delivered to space per year at production costs of 2 - 10 dollars per kg.

During peace time, this launch system can be also used to delivery of mail or express parcels over long distances (for example, from one continent to another) and give a profit 5-10 millions dollars per day.

The figures shows: the estimation of velocity, length of barrel, acceleration via initial pressure air and % of gaseous oxygen in air; loss of velocity in atmosphere via shot velocity; cost delivery via annual payload and cost of installation; etc.

The author has the more detail research this concept and its innovations, which solve problems, which appear in research, computation, development, and design of the suggested Launcher. The author is prepared to submit his research and to discuss the problems with serious organizations wanting to research and develop this invention. Patent applications are 09/013,008; 09/349,235; 10/051,813.

Return to local Contents

Next page 55

Return to main page. Возрaт нa глaвную стрaницу

Число посeтитeлeй с 17 ноября 2002г.

Author proposes a methods of flights to outer Space, described in his book "Non Rockets Flights in Space", which is in preparation for publication.

Author proposes a methods of flights to outer Space, described in his book "Non Rockets Flights in Space", which is in preparation for publication. Abstract

Abstract Abstract

Abstract